Al's Homebrewery - Page 4

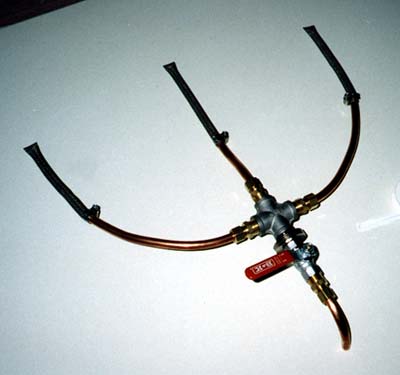

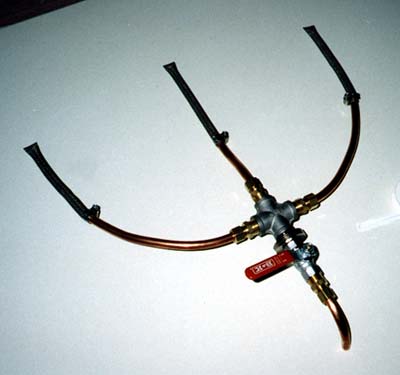

Here's the TridentTM Mash System. Although

I was happy with the EasyMasherTM

in my 8-gallon enamel kettle, I felt that I should get better

efficiency with multiple screens considering the larger cross-sectional

area of the 18.75-gallon kettle. There is a slight downward bend on all

three prongs of the Trident, which places the screens in contact with the

bottom of the kettle. This minimizes the amount of wort that is left behind

after draining.

The brass fittings are 3/8" compression to 3/8" male NPT.

The tubing is 3/8" OD soft copper. The 3/8" ball valve, brass

fittings, copper tubing, hose clamps, teflon tape, and stainless steel

washers (believe it or not!) were purchased at Ace

Hardware. The SureScreensTM at the

ends of the copper are available at many homebrew supply shops or from

Sheaf & Vine.

I bought the stainless steel 3/8" NPT cross and 3/8"

close nipple from McMaster-Carr.

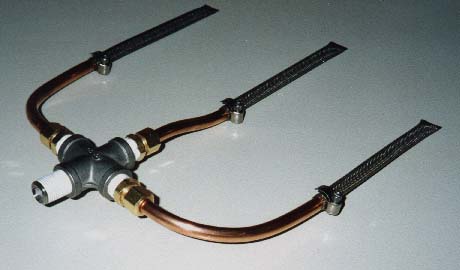

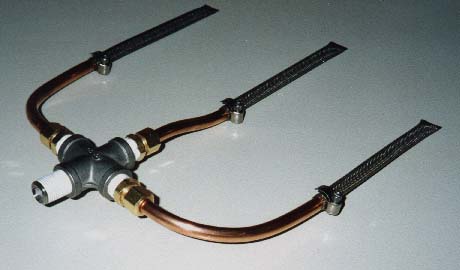

A slightly closer photo shows the assembly after the teflon tape has been

wrapped on the fittings and the fittings have been tightened for a final

fit. The hose clamps may seem optional because the screens fit rather snugly

on the copper tubes, but you want to make sure the screens con't pop-off

during stirring. The outer two prongs of the assembly don't go all the

way to the walls of the mash tun. If they did, this would increase the

likelyhood that sparge water would channel down the smooth walls of the

mashtun and bypass all the sugars trapped in the grain bed. Make sure the

compression fittings are tight: I made one batch where I accidentally

swiveled one of the prongs upwards into the mash. The result was that as

soon as the level of the wort dropped below the top of the highest prong,

air could be drawn into the wort if the runoff rate is too high. Furthermore,

it increases the likelyhood that some sugars will be left in the stagnant

part of the grain bed below the swiveled prong.

Back to Page 3 Next

Page

To the BrewInfo Page (Home)

Copyright © 1997 Al Korzonas - All Rights Reserved